The shortwave radiation emitted by the IR lamps is readily absorbed by the PET preforms, which require reheating before being blown into bottles.

Read more...

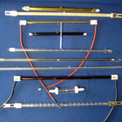

Hi-Heat Ceramic Infrared heating elements emit energy with peak emission wavelengths between 3.3 to 5.7 microns.

Read more...

A shortwave I.R. lamp consists of a coiled tungsten filament in a quartz tube. A combination of a halogen gas and Argon is present in the tube.

Read more...

Portable paint drying equipment with distance sensor and temperature sensor facilitate in touch up of paint and spot repairs.

Read more...